Digital Fabrication and Design - Diploma

Overview

Digital Fabrication is Transforming Industries

As industries modernize and evolve, the shift toward digital design, prototyping and manufacturing has created a high demand for creative problem-solvers skilled in modern manufacturing technologies. Companies need professionals who can bridge digital design with production, utilizing advanced tools, methods and 3D software to create realistic solutions.

If you have a passion for design, enjoy creative problem-solving and are eager to transform your technical aptitude into tangible products, this program is for you.

Whether you dream of working with the latest digital tools or launching your own business, you’ll develop practical, sought-after skills and join a collaborative community of design professionals and digital fabricators.

From Concept to Creation

Acquire the essential skills to become a digital fabricator through a curriculum that is:

- Hands-on: Exploratory, collaborative and structured around projects that simulate industry challenges and current research

- Iterative: Encouraging cycles of prototyping, testing and refining designs

- Interdisciplinary: Integrating concepts from engineering, construction, industrial design, product design, manufacturing and art

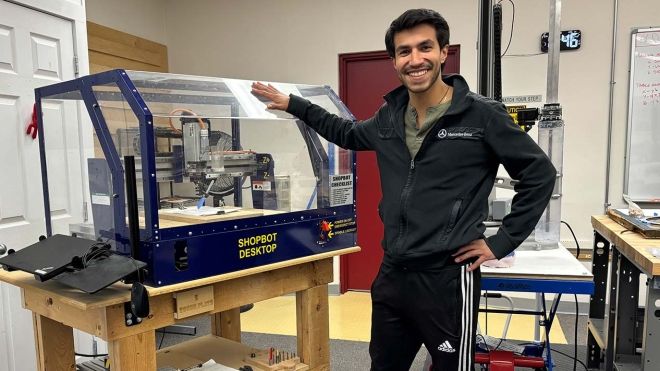

Master Industry-Leading Tools and Techniques

Build a strong foundation in digital fabrication and design with practical experience in:

- Parametric 3D modelling using essential computer-aided design (CAD) software like Fusion 360, Adobe Illustrator and Rhino

- Additive manufacturing (3D printing) and subtractive manufacturing (CNC machining)

- Drafting and 2D drawings that align with industry standard expectations

- Traditional shop skills in metal and woodworking

- Reverse engineering, rapid prototyping, and advanced CNC technologies

As you progress, your studies will expand into metal 3D printing and other technologies shaping the future of manufacturing.

Curriculum that Moves with Industry

Stay current and stay ahead. Learn industry-standard software tools, master the operation of cutting-edge machinery, manage projects, collaborate effectively in teams and thrive in one of Canada’s most comprehensive digital fabrication programs. Access facilities that rank among the most advanced in Canadian colleges, such as the Selkirk College Technology Access Centre. Close ties with local industry ensure a current curriculum aligned with workforce needs in mass timber, architecture, engineering, product design and more.

Your Career, Your Way

Whether you are operating CNC machines, designing mass structures, 3D scanning airplanes or starting your own business, your career in digital fabrication will be as flexible and dynamic as you are. Some of our graduates join product design studios, industrial research labs or tech startups. Others focus on fabrication, programming machines or pushing the boundaries of digital prototyping.

Small Classes, Big Opportunities

Here, you are never just a face in the crowd. With small class sizes and mentorship from industry experts, you’ll have direct access to instructors committed to your growth. Our inclusive, collaborative environment ensures your ideas are heard, supported and developed into meaningful projects.

Now Is the Time

The demand for digital fabricators worldwide is expanding exponentially. If you’re ready to build a career that values innovation, adaptability and hands-on expertise, join a dedicated faculty that celebrates your unique contributions within a dynamic community of makers and industry pioneers.

News

Program Outcomes

Upon successful completion of this program, students will be able to:

- Apply efficient computer-aided design workflows

- Apply 3D-scanning methods and processes for reverse engineering, quality control and metrology

- Apply subtractive and additive manufacturing techniques and efficient workflows for rapid prototyping

- Use current and emerging technologies and recognized best practices

- Apply project planning and evaluation skills

- Operate shop tools and digital fabrication equipment

- Explain terms, concepts and processes of digital fabrication

- Communicate effectively and efficiently in various formats to a variety of stakeholders, consistent with industry expectations

- Apply emerging problem-solving skills

- Demonstrate developing collaborative skills

- Demonstrate developing critical and creative thinking skills

- Conduct themselves in a professional and ethical manner in academic and work-related environments

Admission Requirements

In addition to meeting the general admission requirements to Selkirk College, as outlined in Policy 8611: Admission, applicants to the Digital Fabrication and Design Program must meet the following requirements to be considered fully qualified:

- Math 11 (Foundations or Pre-Calculus) with a minimum of 73% or higher

- English 12 with minimum of 67% or higher

- Completed applicant information questionnaire

- Note: Recommended but not mandatory: Physics 11 with a minimum of 67% or higher

No additional requirements in this program.

APPLICATION PROCEDURE

1. Before an applicant's file is considered to be complete, the following must have been received by the Admissions office:

a) Completed application form.

b) Official transcripts of high school grades (an interim statement of grades is acceptable if applicant is currently a student). Photocopied transcripts are not acceptable unless notarized or submitted directly from the school to Selkirk College.

c) Official transcripts of all post-secondary education grades. Photocopied transcripts are not acceptable unless notarized or submitted directly from the school to Selkirk College.

d) Applicant information questionnaire.

2. Students wishing to enroll in the Digital Fabrication and Design Program on a part-time basis, may do so providing the same entry requirements as full-time students as stated in Part 1.A have been met. Part-time students are only accepted if space is available after all full-time students are scheduled.

CO-OP EDUCATION

This program is eligible for co-op education opportunities. Co-op education courses will provide students with documented, program relevant work experience that is recognized with a designation on their transcript.

Please refer to Policy 8370 Selkirk College Co-operative Education and Selkirk College Co-operative Education Procedures for additional information regarding Co-op Education at Selkirk College.

A. PROMOTION

1. Admission to a given semester requires completion of all required courses with a minimum cumulative G.P.A. of 2.0 and no more than one (1) failure grade in the previous semester courses. Promotion from the first year to the second year also requires a minimum G.P.A. of 2.0 and no more than one failing grade in first year courses. Any student with more than one (1) failure must have the School Chair's approval to progress to the next semester. Students receiving a final grade of "F" in a prerequisite course will not be allowed to register in a subsequent course requiring that prerequisite

2. To be qualified for admission into a course which stipulates a prerequisite, a minimum grade of "C" must be achieved in the prerequisite course, unless otherwise specified.

3. Normally, two failed attempts in a required course is cause for withdrawal from the program. A third attempt in the same course may be made with the permission of the School Chair.

B. GRADUATION

In order to qualify for the Selkirk College Digital Fabrication and Design Diploma, a student must complete all of the following courses with a minimum Final Grade of "P" in each course and an overall GPA of 2.00 or better.

Courses

DFAB103 - Design for Digital Fabrication 2D

DFAB 103 Design for Digital Fabrication 2D will focus directly on a variety of 2D design applications. Students will gain knowledge in communicating design concepts using sketching, graphics, renders, and 2D technical drawing standards.

DFAB104 - Design for Digital Fabrication 3D

DFAB 104 Design for Digital Fabrication 3D. Students will learn how to design for digital fabrication. Emphasis will be put on designing functional parts following industry design standards. This course will focus directly on 3D CAD applications and design practices. Students will gain knowledge in solid and parametric modeling as well as the migration between various workflows and approaches.

DFAB111 - Introduction to Desktop 3D Printing

DFAB 111 Introduction to Desktop 3D Printing introduces students to standard operating and maintenance procedures for common desktop 3D printing machines. Students will receive hands-on training with 3D machines using plastics and plastic alternatives.

DFAB112 - Traditional Fabrication Principles

DFAB 112 Traditional Fabrication Principles introduces students to traditional fabrication processes in relation to equivalent digital fabrication processes. Students will learn standard shop safety practices, measurement techniques, layout and dimensioning standards, how to read and interpret drawings, and applied math skills required for manufacturing. Students will have an opportunity to apply these principles in DFAB 113.

DFAB105 - Design for Additive Manufacturing

DFAB 105 Design for Additive Manufacturing. Design criteria for a variety of additive manufacturing processes will be covered in this course. Students will gain additional knowledge in solid and parametric modeling as it pertains to additive manufacturing design criteria. A variety of design techniques for additive technologies including stereolithography (SLA) and fused deposition modeling (FDM) will be explored.

DFAB106 - Additive Manufacturing I

DFAB 106 Additive Manufacturing I develops student knowledge and skills gained in DFAB 111 related to standard operating and maintenance procedures for additive manufacturing machines, process, and workflows, including safe operation of all systems. Students will receive hands-on training on a variety of additive manufacturing technologies including stereolithography (SLA) and fused deposition modeling (FDM) machines using plastics and plastic alternatives.

DFAB107 - Design for Subtractive Manufacturing

DFAB 107 Design for Subtractive Manufacturing. Design criteria for a variety of 2D subtractive manufacturing processes will be covered in this course. Students will gain additional skills in solid and parametric modeling as it pertains to subtractive manufacturing design criteria. Students will learn a variety of design techniques for subtractive technologies including 2D CNC milling, routing, and laser cutting.

DFAB108 - Subtractive Manufacturing 1

DFAB 108 Subtractive Manufacturing 1. In this course students will learn standard operating and maintenance procedures for subtractive manufacturing machines, processes and workflows, including safe operation of all systems. Students will receive hands-on training on a variety of subtractive manufacturing technologies specifically, 2D CNC routing, milling, and laser cutting for wood, plastic, and other material mediums.

DFAB113 - Traditional Fabrication Practices

DFAB 113 Traditional Fabrication Practices provides students with practical fabrication experience in metal. Students will gain hands-on experience in the application, maintenance, and procedures for the use of hand tools, power tools, layout tools and equipment, drills, drill presses, lathes, and milling machines.

DFAB201 - 3D Scanning and Reverse Engineering

DFAB 201 3D Scanning and Reverse Engineering. In this course students are introduced to reverse engineering where they will learn a variety of techniques including photogrammetry, LiDAR, structured light and machine probing. Students will then focus their learning on scan to CAD, metrology processes and product analysis.

DFAB202 - Subtractive Manufacturing 2

DFAB 202 Subtractive Manufacturing 2. In this course students further their training in CNC manufacturing, building on the knowledge gained in DFAB 108 with a deeper dive into CNC stepping, multi-tool paths, jigging, flipping, and surface contour machining. Students are introduced to sheet metal design in CAD, waterjet cutting, forming and bending techniques. This course explores design considerations, design constraints, safe machine operation, and tool selection for subtractive manufacturing.

DFAB204 - Computer Aided Design and Rapid Prototyping

DFAB 204 Computer Aided Design and Rapid Prototyping. Students will receive an introduction to advanced surface and solid CAD modelling software. Use CAD to create complex solid and surface models. Translate design files between multiple CAD softwares. Explore the relationship between design intent, form giving, and formal resolution through a rapid prototyping exercise.

DFAB205 - Entrepreneurship

DFAB 205 Entrepreneurship supports students to identify and respond to a market need by bringing a marketable business idea to life. By simulating a start up environment, students are challenged to explore team-based problem solving, ideation, and business plan development culminating with a pitch in which students present their startup idea for feedback.

DFAB206 - Molding and Casting for Advanced Manufacturing

DFAB 206 Molding and Casting for Advanced Manufacturing introduces students to the fundamentals of design and implementation of advanced manufacturing. Emphasis is on practical skills including designing for and implementing projects utilizing injection molding, 3D printed mold making and various other molding and casting techniques.

DFAB207 - Advanced CNC Technologies

DFAB 207 Advanced CNC Technologies will introduce students to machining metal using various tools including CNC machining and turning centers. Students will learn standard setup and operation techniques for various machines, how to implement CAD/CAM software to generate the appropriate tool paths, and how to test their learning through CNC simulation before setting up and running the program on physical machines.

DFAB208 - Sustainability and Adaptive Design

DFAB 208 Sustainability and Adaptive Design allows students to apply digital design and fabrication techniques within the context of sustainable product design and adaptive design. Students will complete a series of projects using tools such as 3D solid and surface modeling, 3D scanning technologies, and experimental approaches to digital model generation. Digital models will be made physical through a variety of fabrication technologies which can include 3D printing, CNC milling, casting, molding and laser cutting.

DFAB209 - Capstone

DFAB 209 Capstone provides students with the opportunity to employ their cumulative skills and talents in a chosen area of focused study. Each student must declare an area of interest that will be the basis of a unique product, requiring a series of scheduled tasks to complete.

Tuition & Fees

All amounts are estimates and are subject to change. Tuition amounts are based on a full-time course load. Please note that many programs have additional costs beyond those listed here. For more information, please visit Tuition & Fees.

Find Out More

We look forward to connecting with you! Fill out this form and we'll reach out to you.